Graphite

Purification

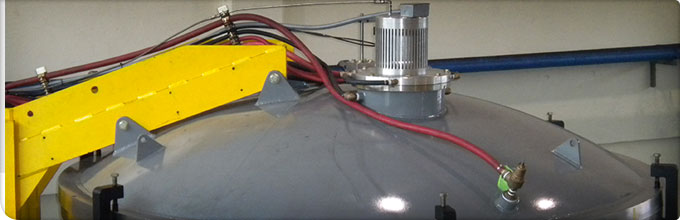

Purification Furnaces

TevTech’s purification equipment utilizes a thermochemical process combining high temperatures with halogen gas to remove metallic impurities. In many applications impurities commonly found in graphite need to be removed in order to prevent migration and or doping of the components being processed. Many of these applications require graphite products with total trace impurities of less than 5 parts per million (5 PPM). TevTech purification systems routinely achieve this specification while utilizing a low halogen per pound of product processed ratio. The minimized halogen usage results in smaller on site storage requirements, reduces the impact on the equipment and reduces effluent streams.

The TevTech Graphite Purification furnaces use a unique heating element design and power distribution system that allows users to reduce high electric current losses.

System Capability

- Custom designed working area's to your specifications.

- Configuration; Vertical or Horizontal loading

- Graphite purified to < 5 ppm impurities.

- Hot Zone Encapsulation Method ensures the cleanliness of the operation and long life of the cold wall furnace chamber and system components.

- The uniquely designed heating element allows for safe and efficient power distribution, with minimal energy losses, to provide an economical way to process large amounts of graphite.

Typical Purification Components

- Gas Storage and Flow Measurement system.

- Vacuum Chamber

- Internal Set Up, Hot Zone, and Heating Element, flow enclosure.

- Power Supply and Power Distribution System.

- Vacuum Pumping System.

- Cooling Water Flow Manifolds and Safety Interlocks.

- Alarms and Interlocks for Safety, Process Deviation, and Equipment Protection.

- Instrumentation and Process Control System

General Design Specifications

| Work Zone Dimensions | Laboratory up to 60" dia. by 80" High |

| Temperature Range | Up to 2300 C |

| Pressure Range | 10m to 760 Torr |

| Furnace Type |

Cold Wall, Stainless Steel, Water Jacket |

| Furnace Configuration |

Vertical with Top or Bottom Loading Mechanism, or Horizontal |

| Hot Zone Material | Graphite with Graphite Felt Thermal Insulation |

| Power Supply | Low Voltage Proportional Reactor |

Optional Equipment Available

- Accelerated Cooling System

- Cooling Water Recirculation System

- Scrubbing System

Carbon Processing Links

- Carbon Processing

- Graphite Purification

- Graphitization

More Information

Please contact TevTech to discuss your specific requirements 978-667-4557 or click here to contact us.

Let our engineers help you develop distinctive solutions to successfully meet your project goals.

Connect with us

Copyright © 2013 TevTech LLC. | 978-667-4557 | sales@tevtechllc.com | 100 Billerica Avenue, North Billerica, MA 01862

Home | Company | News/Press Release | Products | Services | Contact Us

Website Design & SEO by AQ Websites : Website Admin : Sitemap