Sintering & Controlled

Atmosphere

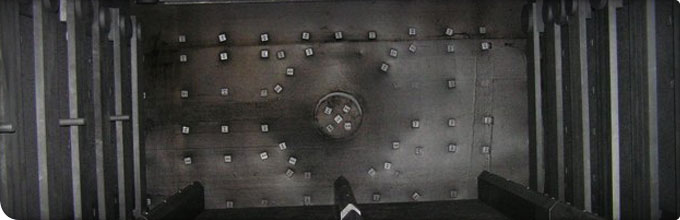

Sintering Furnaces

Our custom designed sintering furnaces provide efficient processing of materials in controlled atmospheres for ceramic and metal sintering, heat treatment and brazing. We have provided revolutionary designs in both metal and graphite hot zones. All TevTech systems are characterized with exceptional control, stability and longevity.

Depending on your product requirements, configuration, production through-put and manufacturing cycle time, the design of your system can vary widely. Let TevTech provide the right system for your company’s current and future plans.

General Design Specifications

|

Sintering Furnace |

Ranges |

|

Hot Zone Dimensions |

Laboratory to 100 ft3 |

|

Temperature Range |

to 2400°C |

|

Pressure Range |

Vacuum to 2 psig |

|

Furnace Type |

Cold Wall, Stainless Steel, Water Jacket |

|

Furnace Configuration |

Horizontal or Vertical with loading mechanism |

|

Hot Zone Material |

Graphite or Metal |

|

Power Supply |

Low Voltage Proportional Reactor |

|

Process Control |

PLC with HMI operator interface or PID Controller |

Ceramic Sintering

Generally the ceramic sintering process is to convert a highly porous compacted powder into high strength uniquely shaped product. Products are used in a variety of applications where high temperature capability, corrosion resistance, and abrasion resistance are required.

Metal Sintering

There are some unique products made from powdered metals that have special heat characteristics. These metals are known as refractory metals. This class of metals is extraordinarily resistant to heat and wear. In the context of materials science and engineering these elements share some interesting properties:

These similarities make them useful in powder metallurgy; where the metal powders are handled similar to ceramic powders. Interesting and complex shapes can be formed and compressed then placed into a high temperature furnace to form finished products or mill shapes for further processing.

Heat Treatment

Heat treatment systems commonly utilize an inert controlled atmosphere to thermally process a product. There are a broad range of process applications, the most comon being brazing, annealing, and curing. Tev Tech has designed a wide variety of heat treatment furnace systems. We have delivered heat treatment systems with graphite and metal hot zones comfigured in several different geometrys, and have operated at ultra high vacuum to positive pressure.

Controlled Atmosphere Links

More Information

Please contact TevTech to discuss your specific requirements 978-667-4557 or click here to contact us.

Let our engineers help you develop distinctive solutions to successfully meet your project goals.

Connect with us

Copyright © 2013 TevTech LLC. | 978-667-4557 | sales@tevtechllc.com | 100 Billerica Avenue, North Billerica, MA 01862

Home | Company | News/Press Release | Products | Services | Contact Us

Website Design & SEO by AQ Websites : Website Admin : Sitemap