Binder

Management

TevTech’s unique approach to Binder Management

TevTech’s Binder Management

Binder burnout is a step in the ceramic sintering process; this step is performed before the furnace is ramped to the sintering temperature. The part is heated until the polymer binder is burned out of the ceramic.

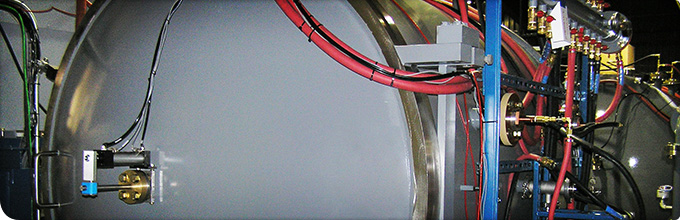

TevTech’s sintering furnaces integrate a unique binder management technique into the furnace. This exclusive design enables our customers to physically remove the unwanted binder material efficiently and completes the full sintering of the ceramic product in the furnace within a single run.

The TevTech binder management addresses the volatile binder during the burn off stage via directing it outside the furnace through a unique combination of gas flow and valves where it can then be handled, minimizing the impact to the hot zone components. Removing the binder from the inside of the furnace and handling it outside results in a significant reduction of between cycle maintenance, can double the life of the hot zone, and will reduce operating cost in your manufacturing.

TevTech provides unique sintering furnaces that have working hot zones ranging from (0.5m3 to 5 m3 ) and temperature capability up to 2400C.

Depending on your product requirements, configuration, production through-put and manufacturing cycle time, the design of your system can vary widely. Let TevTech provide the right furnace for your company’s current and future plans.

Controlled Atmoshere Links

- Controlled Atmoshere & Sintering S

- Binder Management

More Information

Please contact TevTech to discuss your specific requirements 978-667-4557 or click here to contact us.

Let our engineers help you develop distinctive solutions to successfully meet your project goals.

Connect with us

Copyright © 2013 TevTech LLC. | 978-667-4557 | sales@tevtechllc.com | 100 Billerica Avenue, North Billerica, MA 01862

Home | Company | News/Press Release | Products | Services | Contact Us

Website Design & SEO by AQ Websites : Website Admin : Sitemap