CVD Furnaces for Monolithic components

Chemical Vapor Deposition - Monolithic Components (Bulk Material)

TevTech CVD furnaces produce freestanding monolithic materials that are pure and very close to the theoretical density of the material. The CVD process can synthesis reproducible bulk materials with superior performance characteristics.

CVD SiC Monolithic Material

As previously stated silicon carbide is a unique compound; various SiC products are used in many high-temperature applications.

TevTech has delivered remarkably versatile CVD systems used in the manufacture of bulk SiC for many applications.

CVD SiC Bulk Materials Applications

- CVD SiC Etch and RTP rings

- CVD SiC Reflective Optics

- Advanced Micro Electronics

Optical (Infrared) Materials Bulk – ZnS & ZnSe

TevTech provides high temperature vacuum furnaces for manufacture of optical materials specifically for use in the infrared band of the spectrum. This sophisticated CVD process can provide Infrared material like zinc sulfide (ZnS) and zinc selenide (ZnSe). Both ZnS & ZnSe have outstanding strength and surface hardness. These materials are preferred material for use in applications where the optical device will be exposed to unforgiving conditions. Our vacuum furnaces for producing optical materials are specifically designed to improve product consistancy, improve throughput, and reduce operating costs.

Pyrolytic Boron Nitride Bulk - PBN

PBN is an excellent anisotropic ceramic which possesses a unique blend of very high electrical resistance and excellent thermal conductivity. PBN is a non-porous material that can be machined into a variety of physical shapes

Pyrolytic Carbon - PyC

PyC is very high density material; its strength and resistance to fatigue allows bulk PyC to be Pyrolytic carbon is an ultra-pure product. Like PBN it is extremely anisotropic. PyC has highly oriented thermal properties.

SiC Bulk Materials Applications

| CVD Bulk Typical Specification |

Ranges |

|

Depostion Area |

Single or multiple box configuration – Application specific, Net Shape capability |

|

Temperature Range |

to ~1950°C (material dependent) |

|

Pressure Range |

Vacuum to 2 psig |

|

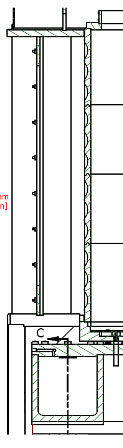

Furnace Type |

Cold Wall, Stainless Steel, Water Jacket |

|

Furnace Configuration |

Vertical with bottom cover loading mechanism |

|

Hot Zone Material |

Graphite with Carbon and Graphite Felt Thermal Insulation |

|

Power Supply |

Low Voltage |

|

Gas Delivery |

Header valves for raw materials supply with pneumatic actuators |

|

Process Control |

PLC with operator interface |

If you need more Information on a CVD material

please click here to contact us.

CVD & CVI Links

- CVD & CVI

- CVD Coating Systems

- CVD Bulk Material

- CVI - Chemical Vapor Infiltration

More Information

Please contact TevTech to discuss your specific requirements 978-667-4557 or click here to contact us.

Let our design team help you develop distinctive solutions to successfully meet your project goals.

Connect with us

Copyright © 2013 TevTech LLC. | 978-667-4557 | sales@tevtechllc.com | 100 Billerica Avenue, North Billerica, MA 01862

Home | Company | News/Press Release | Products | Services | Contact Us

Website Design & SEO by AQ Websites : Website Admin : Sitemap