Graphitization

Graphitization Furnaces

Graphitization

TevTech’s graphitization furnaces provide an economical process for conversion of carbon to a highly uniform, completely crystallized graphite material. Through the use of our uniquely designed high temperature heating elements, hot zone, and power distribution we can convert carbon to graphite at a lower cost.

System Capability

The load size is up to 130 cubic feet per run.

The uniquely designed heating element allows for safe and efficient power distribution, with minimal energy losses, to provide an economical way to process large amounts of graphite.

Typical Furnace Components

- Vacuum chamber with load lifting mechanism

- Graphite hotzone & Graphite heater arrangement

- Power supply & Power distribution system

- Vacuum pumping system

- Inert gas distribution system

- Cooling water manifold arrangement

- PLC Control, Recipe, Safety Alarms and interlocks , Process Deviation & Equipment Status alerts

General Design Specifications

| Work Zone Dimensions | Laboratory sized to 60" dia. by 80" High |

| Temperature Rang |

Up to 2,800°C |

| Pressure Range |

Vacuum to 2 psig |

| Furnace Type |

Cold Wall, Stainless Steel, Water Jacket |

| Furnace Configuration |

Vertical with Bottom Loading Mechanism |

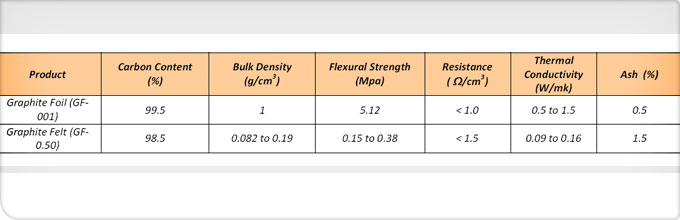

| Hot Zone Material | Graphite with Graphite Felt Thermal Insulation |

| Power Supply |

PLC with touch screen HMI |

Optional Equipment Available

- Accelerated Cooling System

- Cooling Water Recirculation System

Carbon Processing Links

- Carbon Processing

- Graphite Purification

- Graphitization

More Information

Please contact TevTech to discuss your specific requirements 978-667-4557 or click here to contact us.

Let our engineers help you develop distinctive solutions to successfully meet your project goals.

Connect with us

Copyright © 2013 TevTech LLC. | 978-667-4557 | sales@tevtechllc.com | 100 Billerica Avenue, North Billerica, MA 01862

Home | Company | News/Press Release | Products | Services | Contact Us

Website Design & SEO by AQ Websites : Website Admin : Sitemap